new HESTA blow moulding solutions steht für

innovative, zuverlässige und flexible Blasformtechnik

innovative, zuverlässige und flexible Blasformtechnik

Seit Jahrzehnten erfolgreich

Unsere Lösungen

Energieeffizient & Nachhaltig

Unsere Blasformautomaten

Automatisierung

Recycling

AR-Technologie

Turn Key

Verfügbarkeit

E-Learning

Ersatzteile

Energieeffizienz

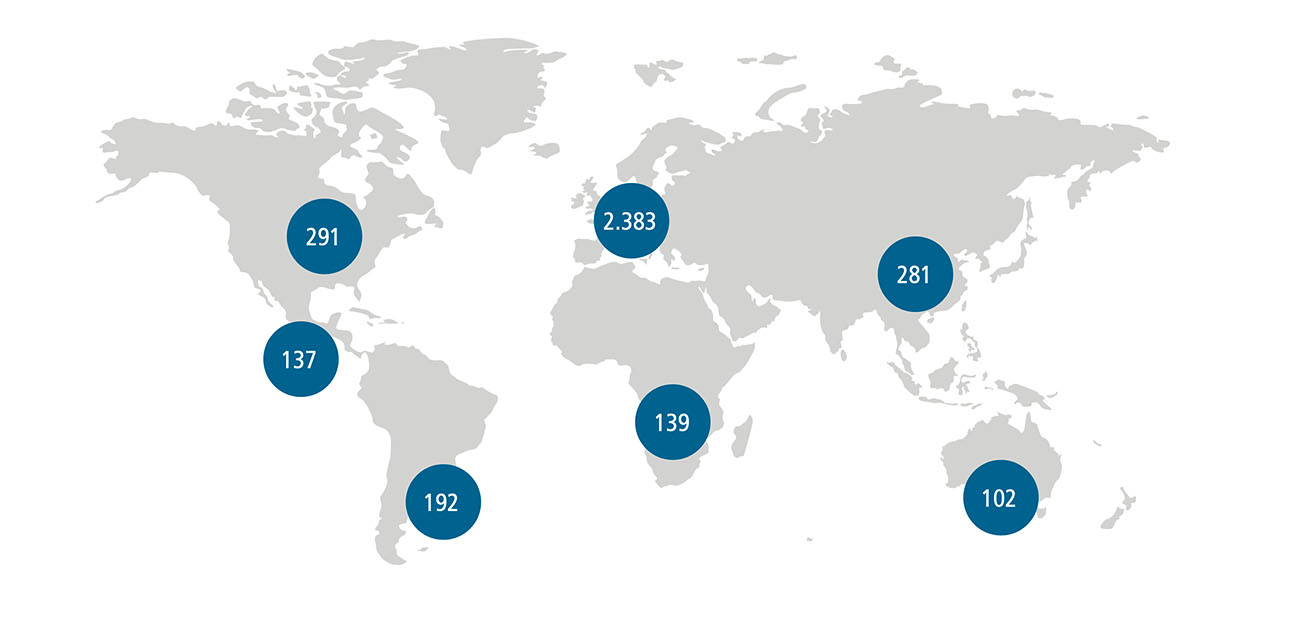

Weltweit für unsere Kunden im Einsatz

Vom Hidden Champion bis zum Multikonzern

Voice Of The Customer

Von dem kleinen Hidden Champion bis zum Multikonzern – wir bieten für all unsere Kunden passende Lösungen an.

Wir gehen individuell auf Ihre Bedürfnisse ein und liefern eine optimale Lösung für Sie und Ihre Endkunden.